Rivnut is now a trademark of BÖllhoff Inc., USA.

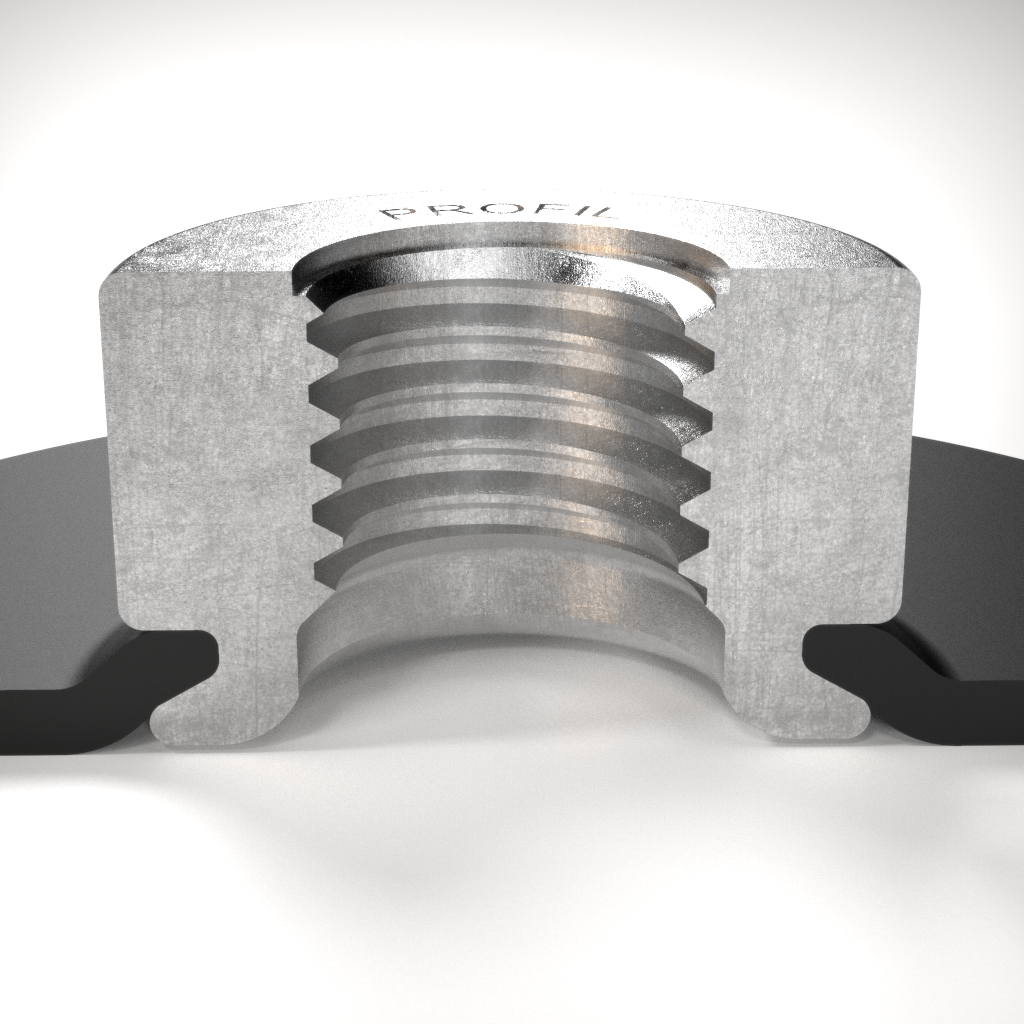

The first rivnut was created by BF Goodrich in the 1930s and sold under the trademark Rivnut ®. During installation, the mandrel of the rivnut tool engages the threaded part of the rivnut and crimps the rivnut body (the part without thread) with a pulling action until the body grips tightly against the material being fastened. RivnutĪ rivnut, also known as rivet nut or nutsert, is a one-piece internally threaded insert that can be anchored from one side of a material to create a permanent and reusable thread. Nutserts are commonly used in industries and applications, including aerospace and agricultural equipment, medical technology, construction, automotive industry, electronic appliances, furniture assembly, HVAC, boat building, playground equipment and more.

They form a solid foundation for other threaded fasteners or screw-in bolts.They are blind fasteners, reliable, strong, and vibration-resistant.Maintaining the rigidity of the joined materials is essential to joint strength and a reliable hold. It also prevents the weakening of substrates due to vibration over time. Compared to a screw or bolt, nutserts are radially swelled to the shape of a hole. They are available in various sizes as well as body and flange shapes. Nutserts are made from different materials, such as: NutsertĪ nutsert, also known as rivet nut, rivnut, or threaded insert, is a one-piece internally threaded insert that can be installed in sheet metal and composite material from one side to create a permanent and reusable thread.Īlthough Nutsert ® is a trademark of Avdel UK Limited, it has become a generic name for any blind threaded insert with a body and flange. Size not listed? Please make an enquiry – we may be able to provide it.Nutsert, Rivet Nut or Rivnut? Ask Rivetlab. = Zinc Plated Steel // = A2 Stainless Steel // = A4 Stainless Steel Non-standard sizes and materials are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings.

Rivet Nut Countersunk Knurled Closed End are available in diameters from M3 to M12 to suit various grip ranges.Īvailable at Fastenright in Zinc Plated Steel, A2 Stainless Steel and A4 Stainless Steel as standard. Installing these rivet nuts is simple, using a special tool with a threaded stud, or nose, that engages with the internal threads of the rivet nut and pulls upwards, deforming the unthreaded section of the rivet nut to expand under the reverse side of the material – providing a high strength permanent thread in a thin sheet material. The closed-end blocks any form of contamination getting to the component, and also prevents the use of screws that are too long for the application. The presence of the knurled body on the rivet nut provides greater resistance to movement within the application than knurling under the head, especially when installed in softer materials. Both types offer a flush, finished appearance to the application. Where the thickness of the application is smaller, the reduced countersunk type is often chosen instead.

#Rivet nuts for plastic full

The full countersunk head is chosen over a reduced countersunk head type due to its stronger nature, however it is also deeper, meaning that it can only be used in material thicknesses greater than 1.5mm.

Rivet Nut Countersunk Knurled Closed End, also referred to as Rivnuts, Blind Nuts and Nutserts®, are an internally threaded insert often used when the thickness of the application at hand is too small to tap a standard thread.īy using rivet nuts, a strong thread is created in thin sheets of material, for high strength fastening from bolts and other threaded articles.

0 kommentar(er)

0 kommentar(er)